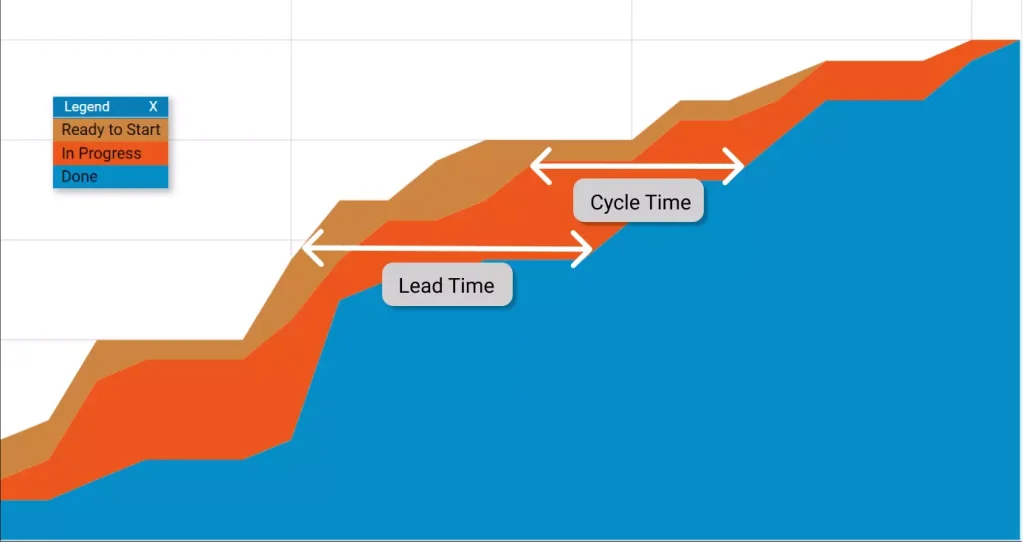

Understanding the difference between cycle time and lead time is essential for improving workflows, optimizing operations, and delivering better results across industries—especially in manufacturing, software development, and project management.

While these two metrics may seem similar, they actually measure different aspects of a process. Cycle time focuses on how long it takes to complete a task from start to finish, while lead time measures the total time from order placement to final delivery. Knowing how to use both effectively can help identify bottlenecks, reduce delays, and improve customer satisfaction.

Let’s dive in and discover how these time-based metrics can transform your productivity.

What Is Cycle Time?

Cycle time refers to the total time it takes to complete a specific task or production process from start to finish. It begins when the actual work starts and ends when the task is completed. This metric is crucial for measuring the efficiency of a process and identifying areas where improvements can be made. Whether you’re developing software, manufacturing products, or delivering services, cycle time gives you a clear view of how long your team takes to complete their work.

Does Cycle Time Include Wait Time?

No, cycle time typically does not include wait time. It only accounts for the actual working time spent on a process. Wait time, downtime, or delays are generally excluded from cycle time and are measured separately to identify inefficiencies. However, in some industries, total cycle time might loosely include these delays if they’re unavoidable within the working phase.

How Do You Calculate Process Cycle Time?

To calculate process cycle time, use the following formula:

Cycle Time = Net Production Time / Number of Units Produced

For example, if it takes 10 hours to produce 100 units, the cycle time per unit is:

Cycle Time = 10 hours / 100 units = 0.1 hour per unit (or 6 minutes per unit)

This formula helps businesses measure how long it takes, on average, to produce a single unit or complete one task.

How to Track Cycle Time?

Tracking cycle time involves the following steps:

Define the start and end points of the task or process clearly.

Use time-tracking tools or software to record the actual work time.

Monitor process steps through visual management tools like Kanban boards or Gantt charts.

Review and analyze the data regularly to identify patterns or delays.

Teams often use project management or workflow automation software to streamline this process and maintain accuracy.

How Does Corexta Help Track Cycle Time?

Corexta simplifies cycle time tracking with powerful automation and reporting features. Here’s how it supports your workflow:

Automated Time Tracking: Corexta automatically logs start and end times for tasks, reducing manual errors.

Customizable Dashboards: Visualize cycle time data in real-time, making it easier to monitor performance.

Performance Insights: Get detailed reports that help identify bottlenecks and inefficiencies in your workflow.

Team Collaboration: Corexta keeps everyone aligned by tracking task progress across departments, ensuring transparency.

With Corexta, businesses can accurately track cycle time, improve efficiency, and make informed decisions based on real-time data.

What Is Lead Time?

Lead time refers to the total time it takes for a product, service, or task to move from the initial request to final delivery. In simple terms, it’s the time between the moment a customer places an order and the moment they receive it. Unlike cycle time, lead time includes everything—processing time, waiting time, shipping time, and any delays along the way.

Lead time is a key performance indicator for businesses, especially in manufacturing, supply chain, logistics, and software development. Shorter lead times often lead to better customer satisfaction, faster delivery, and improved competitiveness in the market.

How to Calculate Lead Time?

The basic formula for calculating lead time is:

Lead Time = Order Delivery Date – Order Request Date

For example, if a customer places an order on July 1 and receives the product on July 10, the lead time is:

Lead Time = July 10 – July 1 = 9 days

In manufacturing or production, lead time can also be broken down into three main parts:

Pre-processing time: time to gather materials or plan production

Processing time: actual time spent on production or service delivery

Post-processing time: packaging, shipping, and delivery to the customer

Understanding each component helps you spot where delays are happening and how to fix them.

How to Track Lead Time?

Tracking lead time requires a clear view of the entire workflow, from order initiation to final fulfillment. Here are the key steps:

Define Start and End Points: Identify when a request is made and when the task or product is delivered.

Use Workflow Management Tools: Software like ERP, project management platforms, or Corexta can help track and timestamp each step.

Monitor Time Spent in Each Phase: Break down the process into segments—procurement, production, shipping—to track where delays occur.

Review Historical Data: Analyze past lead times to spot patterns, outliers, or frequent bottlenecks.

By consistently tracking lead time, businesses can streamline processes, reduce waste, and improve overall delivery performance.

What Is Takt Time?

Takt time is the maximum amount of time you can spend producing a product or delivering a service in order to meet customer demand. It acts as a rhythm or pace-setter for production, helping teams align their workflow with the actual demand. The term “takt” comes from the German word for “pulse” or “beat,” reflecting the tempo at which products must be completed to satisfy customers without overproduction or delays.

Unlike cycle time or lead time, which focus on how long work actually takes, takt time is demand-driven. It’s commonly used in lean manufacturing, agile teams, and production planning to optimize resource allocation and maintain efficiency.

How to Calculate Takt Time?

The formula for calculating takt time is:

Takt Time = Available Production Time / Customer Demand

For example, if your factory operates 480 minutes per day (8 hours) and you need to produce 120 units per day, your takt time is:

Takt Time = 480 minutes / 120 units = 4 minutes per unit

This means you must produce one unit every 4 minutes to meet daily customer demand.

Tracking takt time helps prevent overproduction, minimize waste, and balance workloads across teams.

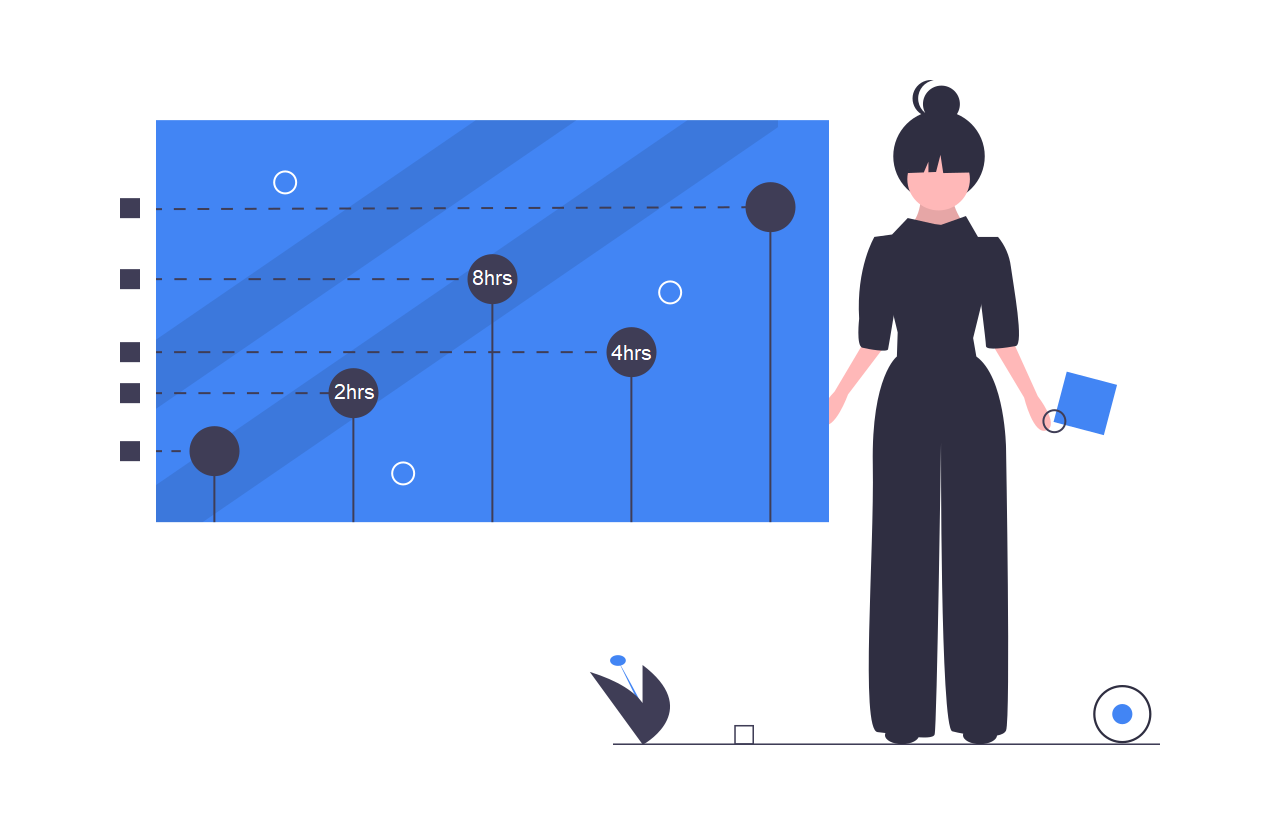

How Does Corexta Help Here?

Corexta helps businesses monitor and align production processes with takt time by offering:

Real-Time Tracking: Corexta provides live dashboards that compare actual cycle times against takt time, ensuring you’re staying on pace.

Demand Forecasting Integration: Corexta can integrate with your sales or demand planning systems to automatically adjust takt time based on updated demand.

Workflow Optimization Tools: Visual tools help identify inefficiencies and make adjustments to processes to match takt time goals.

Alerts & Notifications: Get notified when production slows below takt pace, helping teams take immediate corrective action.

With Corexta, you can stay in sync with customer demand, streamline operations, and reduce unnecessary waste—all by managing takt time effectively.

What Are the Differences Between Cycle Time, Lead Time, and Takt Time?

Although cycle time, lead time, and takt time all measure aspects of time in a process, each serves a different purpose. Understanding their differences is key to improving workflow efficiency, meeting customer expectations, and optimizing resources.

What It Helps With

Cycle Time helps measure the efficiency of a process. It tells you how quickly a team or machine can complete a task from start to finish.

Lead Time focuses on customer satisfaction and responsiveness. It includes the entire duration from order placement to delivery.

Takt Time helps maintain production rhythm. It ensures your production pace aligns with actual customer demand.

What It Considers

Cycle Time considers only the active working time—when work is actually being done.

Lead Time includes everything: waiting time, processing time, shipping time, and delays.

Takt Time considers available work time and customer demand to set a production pace.

How Businesses Use It

Cycle Time is used to:

Identify process bottlenecks

Improve operational efficiency

Track team or machine performance

Lead Time is used to:

Monitor delivery timelines

Improve supply chain reliability

Enhance customer satisfaction

Takt Time is used to:

Match production to customer demand

Prevent overproduction or underproduction

Balance workloads and improve lean operations

Formula

Cycle Time = Net Production Time / Number of Units Produced

Measures how long it takes to produce one unit.Lead Time = Delivery Date – Order Date

Measures total time from order to delivery.Takt Time = Available Work Time / Customer Demand

Sets the pace for production to meet demand.

FAQs about Cycle Time, Lead Time, and Takt Time

What is the difference between manufacturing lead time & throughput rate?

Manufacturing lead time is the total time taken from the start of production to the delivery of the finished product. It includes setup time, processing time, and any delays.

Throughput rate, on the other hand, measures how many units are produced in a given time period. While lead time focuses on duration, throughput focuses on volume and output speed.

What is value stream mapping?

Value stream mapping (VSM) is a lean management technique used to visualize and analyze the flow of materials and information throughout a production process. It helps identify non-value-adding activities (waste), inefficiencies, and areas for process improvement by mapping out every step in the workflow.

What factors negatively affect lead time?

Several issues can increase lead time, including:

Supply chain disruptions

Poor communication between teams

Production bottlenecks

Inventory shortages

Inefficient planning or scheduling

Reducing these delays is key to improving customer satisfaction and staying competitive.

How can you reduce your cycle time?

To reduce cycle time:

Streamline your workflow by eliminating unnecessary steps

Automate repetitive tasks

Improve team collaboration

Invest in efficient tools like Corexta

Use real-time tracking to identify and resolve delays quickly

A shorter cycle time leads to faster delivery and higher productivity.

What is the main goal of Agile?

The main goal of Agile is to deliver value to customers quickly and consistently through iterative development and continuous feedback. Agile focuses on:

Responding to change

Prioritizing working software

Empowering cross-functional teams

Enhancing customer collaboration

Agile encourages flexible planning, early delivery, and ongoing improvement.

Conclusion

Understanding the differences between cycle time, lead time, and takt time is essential for businesses aiming to improve operational performance and customer satisfaction. Each metric plays a unique role:

Cycle time measures internal efficiency

Lead time focuses on the total delivery experience

Takt time aligns production pace with demand

By tracking these metrics effectively and using tools like Corexta, businesses can streamline their processes, meet deadlines more consistently, and build stronger relationships with their customers. Mastering these time metrics isn’t just about speed—it’s about working smarter and delivering real value.