In today’s fast-paced business environment, time is more valuable than ever. Delays in processes—especially in project management and production—can result in missed deadlines, frustrated teams, and lost revenue. One of the biggest culprits behind these delays is lag time, a period when tasks are idle due to waiting or poor planning.

Whether you’re managing a small team or overseeing a large-scale project, optimizing workflows to reduce lag time is essential for improving productivity and ensuring smooth operations. By identifying bottlenecks, streamlining communication, and strategically planning task sequences, you can dramatically cut down on wasted time. This blog will guide you through understanding lag time and provide actionable strategies to optimize workflows and boost efficiency.

What is Lag Time?

Lag time refers to the delay or gap between two connected tasks in a workflow or project schedule. It is the period when one task finishes, but the next dependent task doesn’t begin immediately. In project management terms, this gap may be intentional—allowing materials to dry, approvals to process, or data to be reviewed—or it may signal inefficiencies in planning.

For example, if Task A ends on Monday and Task B doesn’t start until Wednesday, there is a two-day lag. While some lag time is planned and necessary, excessive or unmonitored lag can lead to significant delays and productivity loss. Understanding where and why lag time occurs is the first step to managing it effectively.

Comprehensive Overview of Lag Time in Project Management

Lag time is a crucial concept in project management that, when misunderstood or mismanaged, can cause significant workflow disruptions. By diving deeper into how it is calculated, its key characteristics, and its practical purposes, you can gain better control over your projects and prevent unnecessary delays.

How is Lag Time Calculated?

Lag time is typically calculated as the duration between the finish of one task and the start of its successor in a dependent relationship. In most project management tools (like Microsoft Project, Asana, or Primavera), you define dependencies between tasks using Finish-to-Start (FS), Start-to-Start (SS), Finish-to-Finish (FF), or Start-to-Finish (SF) relationships. Lag time is inserted as an intentional delay within those dependencies.

For example, if Task A (painting a wall) finishes on Day 3, and Task B (installing shelves) starts on Day 6, there is a lag time of 3 days. In a Gantt chart, this gap appears as the time interval between the two tasks.

Formula Example:

Lag Time = Start Date of Task B – Finish Date of Task A

Lag time can be positive (indicating a delay), zero (no lag), or even negative—known as lead time, where Task B starts before Task A finishes.

What are the Characteristics of Lag Time?

Lag time has several defining characteristics in the context of project management:

Time-Based Delay: Lag time is always measured in units of time (hours, days, weeks) and represents a scheduled pause between tasks.

Intentional or Unintentional: It may be built into the project timeline for practical reasons, or it might arise due to poor planning or unforeseen delays.

Affects Critical Path: Excessive lag time can impact a project’s critical path, pushing back deadlines and increasing project duration.

Dependency-Specific: Lag only occurs between tasks that have logical relationships (such as Finish-to-Start).

Modifiable: With efficient project oversight, lag time can often be reduced or optimized without affecting task quality.

What is the Purpose of Lag Time?

While lag time might sound counterproductive, it often serves specific, strategic purposes in a project schedule:

Allowing for Natural Delays: Some tasks require time to settle or complete beyond their immediate finish. For example, concrete needs curing time before construction can continue.

Ensuring Quality Assurance: Time between tasks may be needed for inspection, review, or approvals to maintain quality standards.

Managing Resource Availability: Sometimes, a delay is necessary to wait for specific equipment or personnel to become available.

Enabling Risk Mitigation: Introducing lag time between critical tasks can act as a buffer to absorb potential risks or errors.

Coordination Across Teams or Departments: Lag time helps align multi-team activities that depend on external input or handoffs.

By purposefully using lag time, project managers can improve coordination, maintain workflow integrity, and reduce the risk of cascading errors.

What are Some Commonly Used Lagging Indicators in Project Management?

Lagging indicators are metrics that reflect the outcomes of past actions or decisions. Unlike leading indicators, which predict future performance, lagging indicators help assess how well a project has performed up to a certain point. These indicators are useful for identifying inefficiencies—including excessive lag time.

Here are some commonly used lagging indicators in project management:

Actual vs. Planned Schedule Variance: Compares planned deadlines with actual completion dates, revealing delays.

Budget Overrun: Measures whether the project has stayed within budget or experienced financial lag.

Milestone Achievement Rate: Tracks how often key milestones are met on time.

Cycle Time and Lead Time: Although they track production timing, increases in these may suggest lag issues elsewhere.

Client Satisfaction Scores or Stakeholder Feedback: While not time-based, dissatisfaction often stems from project delays and inefficiencies.

By monitoring these indicators, project managers can pinpoint areas where lag time is hurting performance and take corrective action to optimize workflows.

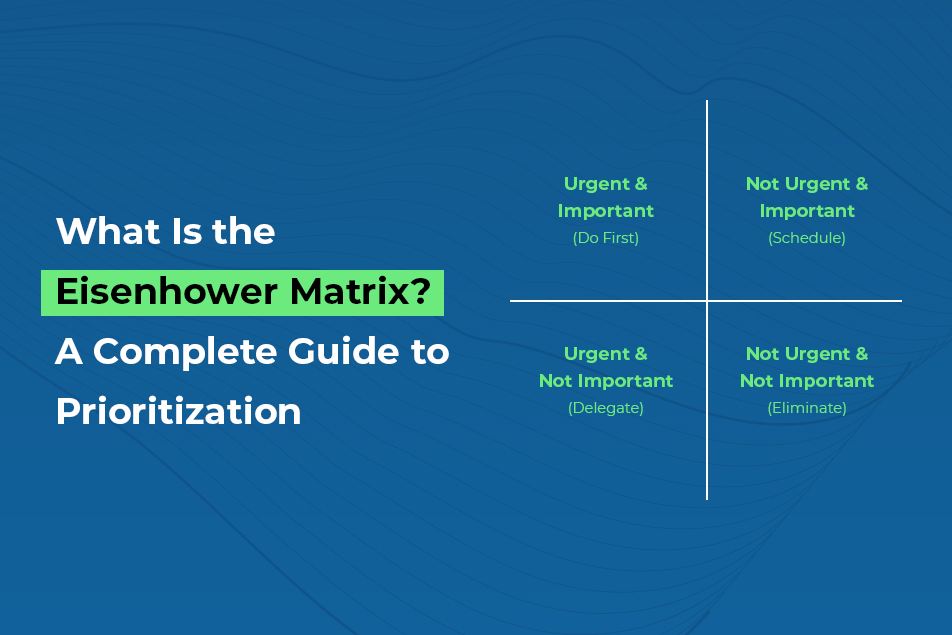

Lead Time vs. Lag Time

Understanding the distinction between lead time and lag time is essential in effective project planning. While both terms deal with timing and scheduling, they serve very different purposes in workflow management.

Lead Time refers to the total time it takes to complete a process—from the initiation of a task to its delivery or completion. It includes active work time and waiting periods.

Lag Time, on the other hand, is the intentional or unintentional delay between dependent tasks, where one task must pause before the next begins.

Let’s break down how both impact key areas of project management:

Planning and Scheduling

Lead Time:

Lead time plays a critical role in long-term project scheduling. It helps managers estimate how long a series of tasks or deliverables will take from start to finish. Accurate lead time calculation ensures realistic project timelines and helps allocate resources accordingly.

Lag Time:

Lag time directly affects short-term planning and task sequencing. It must be carefully scheduled to prevent unnecessary delays. Overlooking lag time can result in gaps between tasks that accumulate and throw off the entire project schedule.

Key Insight:

Minimizing lag time helps tighten lead time, creating a more streamlined project plan.

Resource Utilization and Optimization

Lead Time:

Managing lead time efficiently can lead to better forecasting and resource planning. When lead times are reduced, teams can move quicker, inventory levels are optimized, and project deliverables arrive faster.

Lag Time:

Excessive lag time can lead to underutilized resources. For example, if a team is waiting several days between tasks, their productivity drops. By reducing unnecessary lag, project managers can keep resources actively engaged.

Key Insight:

Controlling lag time ensures that skilled personnel, equipment, and materials are used efficiently without long idle periods.

Performance Management

Lead Time:

Tracking lead time over the course of a project helps evaluate how efficiently the workflow is moving. A project with consistently low lead times usually reflects strong execution and fast delivery.

Lag Time:

Lag time is a direct indicator of workflow bottlenecks or delays. By analyzing lag between tasks, managers can uncover process flaws, communication gaps, or approval delays that hinder performance.

Key Insight:

Monitoring both lead and lag time helps identify areas for performance improvement and keeps the project on track.

Accountability

Lead Time:

Lead time reflects the overall responsibility of teams and stakeholders from project start to completion. When deadlines are missed, long lead times often point to broader systemic issues or underperformance.

Lag Time:

Lag time places focus on specific gaps between responsibilities. For instance, if Task A ends and Task B doesn’t begin for several days, the delay might be due to a particular team or decision-maker. This helps assign accountability more accurately.

Key Insight:

Lag time can highlight where specific breakdowns are occurring, making it easier to hold the right individuals or departments accountable.

Factors Affecting Lead & Lag Time in Production

In production and manufacturing environments, lead time and lag time are vital metrics that influence delivery schedules, operational efficiency, and customer satisfaction. Both are shaped by various internal and external factors that can either accelerate or delay your overall workflow. Understanding these influences is key to identifying bottlenecks and improving process flow.

Here are the major factors that affect lead and lag time in production:

1. Supply Chain Efficiency

The speed and reliability of your suppliers directly impact lead time. Delays in raw material procurement, shipping, or inventory replenishment can cause extended lead times and force a lag between production stages.

Unreliable vendors

Customs and import delays

Poor inventory control

2. Production Scheduling and Planning

A lack of precise planning often introduces gaps (lag time) between production phases or results in extended lead times due to inefficiencies.

Inaccurate forecasts

Overlapping jobs and overloading machines

Manual vs. automated scheduling systems

Properly mapping out each task and managing dependencies helps avoid unplanned delays.

3. Workforce Availability and Skill

Labor shortages, skill mismatches, or untrained workers can lead to slower output (increased lead time) and pauses between task transitions (lag time).

Sick leaves or staff turnover

Inadequate shift planning

Dependency on specialized labor

4. Equipment and Machinery Readiness

Unscheduled downtime, maintenance issues, or machinery breakdowns can significantly increase lag time between production phases and extend lead times.

Lack of preventive maintenance

Limited access to backup equipment

Long setup or changeover times

5. Quality Control and Rework

Quality inspections that take too long—or worse, frequent reworks—can stretch both lead and lag time.

Detailed inspections between steps

Non-conformances or product rejections

Manual documentation and reporting

While necessary for product integrity, if not optimized, these processes can become major time drains.

6. Communication and Coordination

Lack of real-time communication between teams, departments, or supply chain partners can cause delays in decision-making or task initiation.

Delayed approvals

Unclear handoffs between departments

Lack of workflow visibility

Improving communication systems can eliminate unnecessary lag time caused by waiting for responses or next steps.

7. Technology and Automation

Modern ERP and project management systems can streamline scheduling, inventory, and quality control—reducing both lead and lag time. Conversely, outdated or fragmented systems often increase delays.

Manual data entry or reporting

Disconnected systems across teams

Lack of workflow automation

8. External Factors

Events beyond organizational control can have a major impact on timelines.

Natural disasters

Geopolitical issues

Economic fluctuations

Supplier bankruptcy

While you can’t eliminate these risks, having a buffer and contingency plan helps mitigate their impact on both lead and lag time.

How to Handle and Manage Lag Time in Project Management

Lag time is a natural part of project schedules—but when left unmanaged, it can become a hidden source of delay and inefficiency. The good news is that with the right strategies and tools, project managers can control, reduce, and even eliminate unnecessary lag time. Here’s how to handle lag time effectively in your projects:

1. Map Dependencies

Before tackling lag time, you need a clear understanding of how tasks relate to one another. This means identifying and mapping all task dependencies in your project.

Use project management tools like Gantt charts, dependency matrices, or critical path analysis to visualize task sequences.

Clearly define whether tasks are Finish-to-Start (FS), Start-to-Start (SS), or another relationship.

Identify where delays are acceptable (planned lag) and where they are not (unplanned lag).

Why it matters:

When you know how tasks depend on each other, you can pinpoint where lag time exists—and whether it’s necessary or can be eliminated.

2. Track Time Accurately

Time tracking is vital for spotting lag time early. Without proper records, you won’t know how long tasks actually take—or how long things are sitting idle between them.

Use digital time-tracking tools to monitor task durations and transition gaps.

Compare actual start and end times with planned schedules.

Log delays and idle times with notes on causes and responsible teams.

Why it matters:

Detailed tracking helps you see patterns and address issues that lead to recurring or excessive lag time.

3. Schedule Right

Effective scheduling goes beyond setting dates. It involves building realistic timelines that account for necessary lags, while avoiding unnecessary ones.

Avoid over-buffering tasks—build in just enough lag where absolutely needed (e.g., drying time, inspection periods).

Balance workloads to prevent idle teams waiting for dependencies to be completed.

Adjust schedules in real time as tasks are completed early or delayed.

Why it matters:

Smart scheduling keeps the project moving and minimizes delays caused by poor task sequencing or unrealistic planning.

4. Communicate Clearly

Miscommunication is one of the biggest causes of unplanned lag time. Teams that don’t know when to start, what’s been completed, or what’s expected next often stall progress.

Maintain real-time updates on task statuses through collaboration platforms.

Hold brief but consistent check-ins to align teams and clarify responsibilities.

Define clear handoffs between tasks and teams to ensure smooth transitions.

Why it matters:

When everyone is informed and in sync, lag time caused by confusion or silence is greatly reduced.

5. Most Importantly, Monitor and Optimize

Managing lag time is not a one-time task—it’s an ongoing process. To truly prevent workflow delays, you must continually monitor project performance and optimize based on data.

Use dashboards and reports to track lag time trends.

Conduct post-project reviews to analyze where lag occurred and why.

Continuously refine task dependencies, durations, and schedules based on real-world results.

Why it matters:

Ongoing optimization ensures your workflows get faster, smoother, and more efficient over time.

Pro Tip:

Consider using project management software like Corexta, Trello, or ClickUp. These tools make it easier to manage dependencies, visualize timelines, and track time—all in one place.

Streamline Your Project Workflows and Eliminate Lag Time with Corexta

Every project involves a series of interconnected tasks—and delays caused by waiting on others can throw everything off track. While some lag is unavoidable, effective project management focuses on reducing it as much as possible.

If you want to deliver your project on time, within scope, and on budget, minimizing lag time is non-negotiable. That’s where Corexta comes in.

Corexta’s all-in-one project management platform is built to help you eliminate workflow delays. From accurate time estimates to real-time progress tracking, it gives you the tools to stay ahead of schedule and keep your team aligned.

Stay efficient. Stay on time. Start using Corexta for free today!

FAQs About Lag Time

1. What is an example of lag time?

An example of lag time in project management is when a wall is painted (Task A), and the next task—mounting shelves (Task B)—cannot begin until the paint dries. If the paint takes two days to dry, this two-day gap is considered lag time. It’s a planned delay built into the schedule to ensure that Task B doesn’t start prematurely.

2. What is another word for lag time?

While “lag time” is a commonly accepted term, it may also be referred to as:

Delay

Idle time

Slack time (though this can differ slightly in meaning)

Inter-task gap

These terms often describe the same concept: a pause or waiting period between dependent tasks.

3. What is lag time and lead time?

Lag time is the delay between two dependent tasks where the successor does not begin immediately after the predecessor ends.

Lead time, on the other hand, is the total time from the initiation of a task or order to its completion—including processing and waiting time. In scheduling terms, lead time can also refer to a situation where a task starts before its predecessor ends (negative lag).

In summary:

Lag Time = Delay between tasks

Lead Time = Total time to deliver a result